Describe the Terminology Used for Welding Positions

Gas tungsten arc welding GTAW - An arc welding process which produces coalescence of metals by heating them with an arc between a tungsten non-consumable electrode and the work. Describe the terminology used for the appropriate welding positions 212 explain how to prepare the materials in readiness for the welding activity such as ensuring that the material is free from excessive surface contamination - such as rust scale paint oilgrease and moisture.

Welding Joint Types Butt Joints Lap Joints Tee Joints More

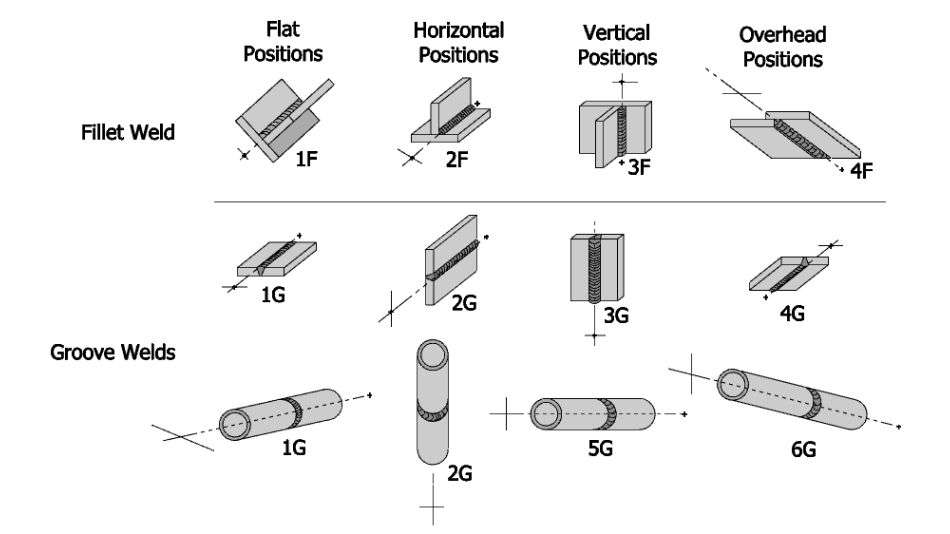

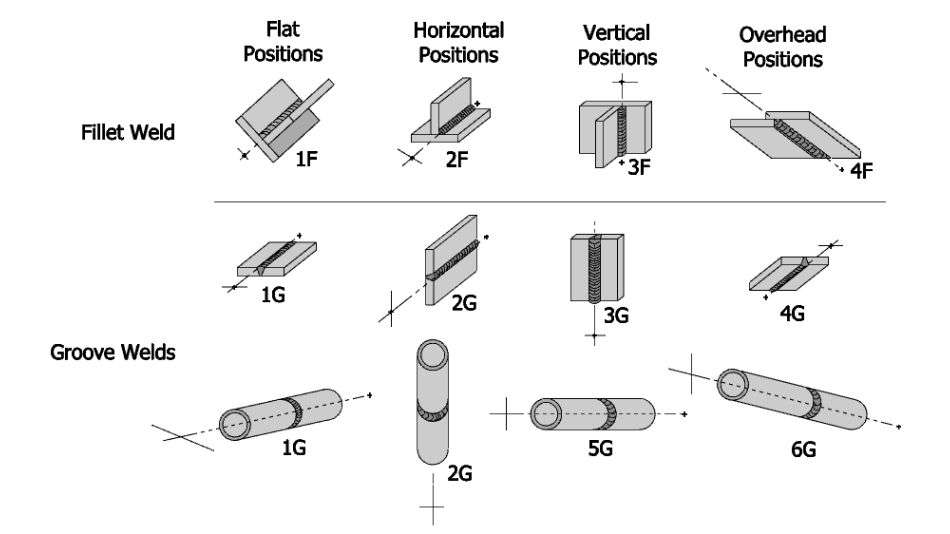

Overhead 4F For Groove welds following are the welding positions defined.

. The main problem faced with a vertical weld is that the molten metal tends. Describe the terminology used for the appropriate welding positions. Explain how to prepare the materials in readiness for the welding activity such as ensuring that the material is free from excessive surface contamination - such as rust scale paint oilgrease and moisture.

A cutting process in which a gas flame is used to cut metals. This is an out of position welding position. Welding instruction in various positions on joint designs.

Welding Positions a reference to the positional aspects of welding. Basic Welding Terms and A-Z Glossary. Normally the following numbers and letters are used.

A process in which bonding is produced by heating with a molten nonferrous filler metal poured over the joint until the brazing temperature is attained. INTRODUCTION TO GAS TUNGSTEN ARC GTAW WELDING LECTURE 3 LAB 4. A welding process in which a gas flame is used to create the welding heat.

Chip Test is a test that is used to identify a metal. Describe the types of welded joints to be produced such as lap joints corner joints tee joints and butt welds 10. What Is a Welding Position.

Aspiring people can find all the terminology on our website WeldingInfo. The shortest distance between the weld root and the face of a fillet weld. The vertical welding position describes a weld with the axis being vertical.

Ensuring edges to be welded are correctly prepared - such as made flat square or bevelled 13. Electrode diameter is welding range from 316 to 332 of an inch. For Fillet welds following are the welding positions defined.

Introduction to Shielded Metal Arc Welding Stick 65 Hours Description. Also when a welder is given a mechanical drawing he or she needs to be able to understand the type and location of the welds to be made by reading the. Its a more difficult.

Conventionally a number is used to describe the position and a letter is used to indicate the type of weld F for Fillet and G for Groove. Although the terms flat horizontal vertical and overhead sufficiently describe the positions for plate welding they do not adequately describe pipe welding EXPANSION AND CONTRACTION positions. Air Carbon Arc Cutting CAC-A.

In ISO 15614-1 ASME IX and AWS D11 referring to AWS A30 the ideals are pretty similar but have a different naming system. The most common type of gas welding is oxyfuel welding. Most conversations about welding usually begin with a discussion on welding positions.

Overhead 4F For Groove welds following are the welding positions defined. Welding Positions are the positional relation between the welder and the production piece to be welded. Basic understanding of symbols used in we.

4 Basic Welding Positions Flat Position 1G and 1F. Describe the terminology used for the appropriate welding positions 12. The easiest type to perform is the flat position which is also sometimes called the downhand.

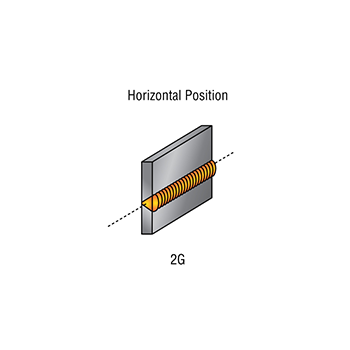

For groove welding positions-1G flat welding position 2G horizontal welding position 3G vertical welding position 4G welding position overhead or overhead 5G uphilldownhill vertical welding position. The horizontal position is considered an out-of-position weld. For Fillet welds following are the welding positions defined.

Horizontal Position 2G and 2F. Gas welding is mainly used for repair work as well as the welding of pipes and tubes. The position in which welding is performed from the upper side of the joint and the face of the weld is approximately horizontal.

- A general term used to describe gas metal arc welding gas tungsten arc welding and flux cored arc welding when gas shielding is employed. A cutting process by which metals are melted by the heat of an arc using a carbon electrode. Molten metal is forced away from the cut by a.

The weld axis is horizontal. For detailed information on welding definitions follow the link. The field of welding uses standardized terminology to describe the various welding joints and welding positions that every welder must know.

Thus the above-mentioned were some of the examples from the A to Z basic welding terms. This weld is more complicated than both the flat and horizontal positions however. In this position the welding is performed from the upper side of the joint and the face of the.

Larger diameter electrode are used on thicker metals and for flat positions welding because the. In pipe welding there are four basic test When apiece of metal is heated the metal expands. Grove and Fillet Welding Positions.

The Diamater is based on the thickness of the base metal the welding position and the type of joint. The axis of a weld is a line through the length of the weld perpendicular to the cross. Also referred to as a downhand position the flat position weld is the easiest and often the first.

Introduction to Shielded Metal Arc Welding will cover the basic theory and hands on practice as well as common operation procedures needed to perform the SMAW processDefinitions and terminology commonly used in welding. 1 refers to a Flat position either 1G or 1F 2 refers to a Horizontal position either 2G or 2F. Ensuring edges to be welded are correctly prepared - such as made flat square or bevelled 213 explain.

This course is an introduction to the principles of gas tungsten arc welding GTAW setup and use of GTAW equipment and safe use of tools and equipment. This chapter will introduce and explain many essential welding vocabulary terms. Describe the gas pressures and flow rates in relationship to the type of material being welded 9.

Welding Positions Flat Welding Positions.

What Is Smaw Welding Procedure Shielded Metal Arc Welding Arc Welding Smaw Welding

Types Of Welding Positions Welder Portal

Welding Resumes Examples Job Resume Examples Resume Objective Examples Cover Letter For Resume

What Are The 5 Mig Welding Positions A Definitive Guide Welders Lab

Arc Welding Processes Ahss Guidelines

Free Guide To 700 Welding Terms Welding Projects Beginner Welder Diy Welder Welding Welding Books

What Is A Welding Position Why Are There Different Welding Positions What Is The 1g 2g 5g 6g Pipe Welding Positions

What Are The 5 Mig Welding Positions A Definitive Guide Welders Lab

Types Of Welding Positions And 1g 2g 3g 4g 5g 6g 6gr Joint Types

Welding Joint Types Butt Joints Lap Joints Tee Joints More

Solenoid Valves Terminology Refrigeration And Air Conditioning Valve Hydraulic Systems

Welding Technology Set Up Smaw Equipment Welding Stick Welding Tips Welding Machine

Shielded Metal Arc Welding An Overview Sciencedirect Topics

Welding Positions A Reference To The Positional Aspects Of Welding

Types Of Welding Positions And 1g 2g 3g 4g 5g 6g 6gr Joint Types

What Are The 4 Basic Welding Positions And When Should You Use Them Millerwelds

Comments

Post a Comment